Download

Overview

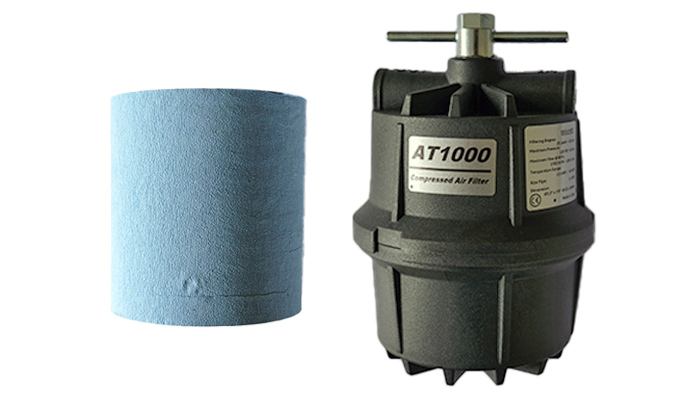

Introducing the AT 1000 the ultimate solution to combat the issues of contaminated compressed air in plasma cutting systems. Say goodbye to moisture and oil from compressed air lines, extend the life of your electrode and nozzle, and improve the quality of your cut with this essential tool.

Designed specifically to remove aerosol oil and moisture, the AT 1000 offers unparalleled filtration, trapping particles as small as .01 microns. This means your torches last longer, and you can enjoy the benefits of improved cut quality without the worry of condensed moisture causing a short circuit.

Capable of filtering up to 1250 liters per minute without any reduction in pressure, the AT 1000 is perfect for those who demand high performance and efficiency. Plus, it’s not just limited to plasma cutting systems – it’s also ideal for use with pneumatic tools and painters.

Our expertise in the production of plasma cutting torches and extensive knowledge of air contaminants led us to create the AT 1000. With a recommended filter cartridge replacement of every 5 to 7 days

(maximum), this powerful filter is an essential addition to your arsenal. Say goodbye to costly replacements and time-consuming maintenance with the AT 1000.

Key Benefits of AT-1000

Improved Cut Quality

High Flow Rate

highly efficient and effective.

Low Maintenance

of the AT 1000 system simple and hassle-free cut quality.